Splashbacks

Home / Shop / Kitchen / Splashbacks / Page 3

Tiling your splashback is one of the simplest ways to add class to your interior. Tiled splashbacks are perfect for kitchen benches, bathroom basins, and other wet areas. Browse the gallery below for inspiration.

-

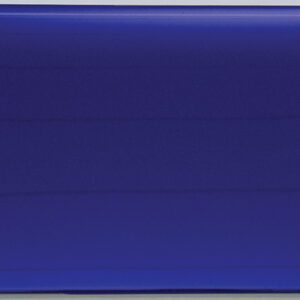

Maxglass Shape Royal 75x150mm

$3.40 each(incl GST) -

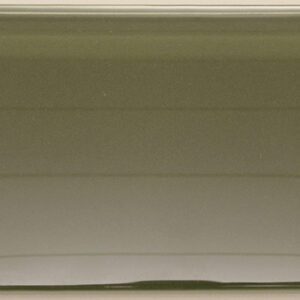

Maxglass Shape Seaweed 75x150mm

$3.40 each(incl GST) -

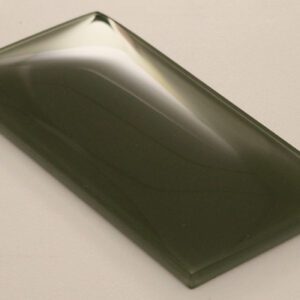

Maxglass Shape Storm 75x150mm

$3.40 each(incl GST) -

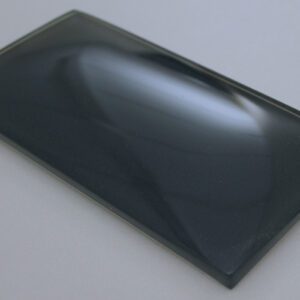

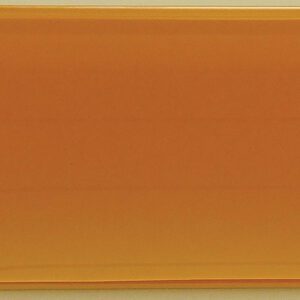

Maxglass Shape Sunflower 75x150mm

$3.40 each(incl GST) -

Maxstone Classic Alabaster 100x100mm

$3.50 each(incl GST) -

Maxstone Classic Alabaster Insert 35x35mm

$0.50 each(incl GST) -

Maxstone Classic Alabaster Octagon 305x305mm

$31.50 per sheet(incl GST) -

Maxstone Classic Alabaster Strip 25x100mm

$1.60 each(incl GST) -

Maxstone Classic Alabaster/Cafe Florence 406x406mm

$79.90 per sheet(incl GST) -

Maxstone Classic Alabaster/Cafe Milan Border 130x330mm

$29.90 per sheet(incl GST) -

Maxstone Classic Cafe 100x100mm

$3.50 each(incl GST) -

Maxstone Classic Cafe Insert 35x35mm

$0.50 each(incl GST) -

Maxstone Classic Cafe Strip 25x100mm

$1.60 each(incl GST) -

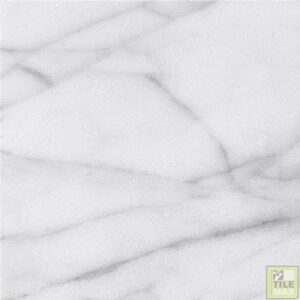

Maxstone Classic Carrara 100x100mm

$3.50 each(incl GST) -

Maxstone Classic Carrara Insert 35x35mm

$0.50 each(incl GST) -

Maxstone Classic Carrara Octagon 305x305mm

$31.50 per sheet(incl GST) -

Maxstone Classic Carrara Pisa 310x305mm

$34.90 per sheet(incl GST) -

Maxstone Classic Carrara Strip 25x100mm

$1.60 each(incl GST) -

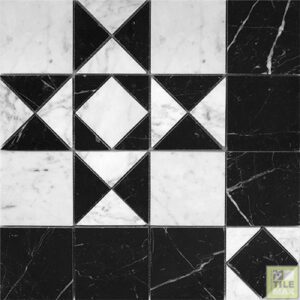

Maxstone Classic Carrara/Marquina Florence 406x406mm

$79.90 per sheet(incl GST) -

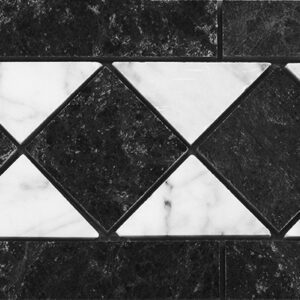

Maxstone Classic Carrara/Marquina Milan Border 130x330mm

$29.90 per sheet(incl GST) -

Maxstone Classic Carrara/Verde Florence 406x406mm

$79.90 per sheet(incl GST) -

Maxstone Classic Carrara/Verde Milan Border 130x330mm

$29.90 per sheet(incl GST) -

Maxstone Classic Marquina 100x100mm

$3.50 each(incl GST) -

Maxstone Classic Marquina Insert 35x35mm

$0.50 each(incl GST) -

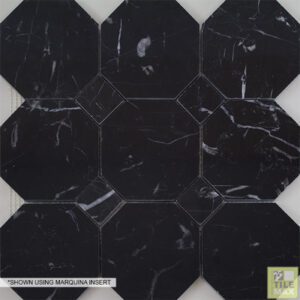

Maxstone Classic Marquina Octagon 305x305mm

$31.50 per sheet(incl GST) -

Maxstone Classic Marquina Strip 25x100mm

$1.60 each(incl GST) -

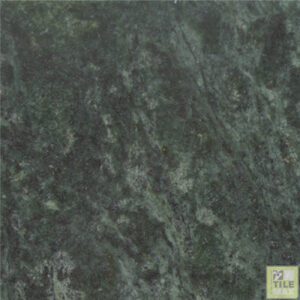

Maxstone Classic Verde 100x100mm

$3.50 each(incl GST) -

Maxstone Classic Verde Insert 35x35mm

$0.50 each(incl GST) -

Maxstone Classic Verde Strip 25x100mm

$1.60 each(incl GST) -

Metal Stone Silver Random Mosaic

$39.90 per sheet(incl GST) -

Metro Black Gloss Wave 65x400mm

$74.90 per m2(incl GST) -

Metro Black Satin Flat 60x400mm

$74.90 per m2(incl GST) -

Metro Black Satin Flat 65x400mm

$74.90 per m2(incl GST) -

Metro Dark Grey Gloss Wave 65x400mm

$69.90 per m2(incl GST) -

Metro White Gloss Flat 65x400mm

$64.90 per m2(incl GST) -

Metro White Satin Flat 60x400mm

$64.90 per m2(incl GST) -

Metro White Satin Flat 65x400mm

$64.90 per m2(incl GST) -

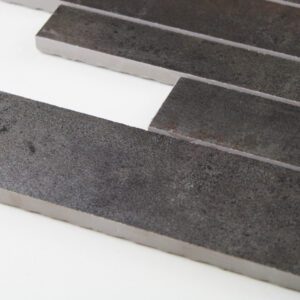

Mi Incarico Gris Random Mosaic

$39.90 per sheet(incl GST) -

Mi Incarico Nero Random Mosaic

$39.90 per sheet(incl GST) -

Mojave Blu Brick 60x250mm

$159.50 per m2(incl GST) -

Mojave Denim Brick 60x250mm

$159.50 per m2(incl GST) -

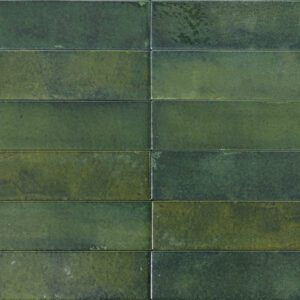

Mojave Green Brick 60x250mm

$159.50 per m2(incl GST) -

Mojave Light Grey Brick 60x250mm

$159.50 per m2(incl GST) -

Mojave Sea Water Brick 60x250mm

$159.50 per m2(incl GST) -

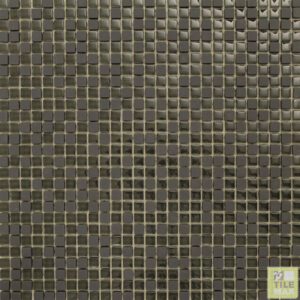

MosaicFX Artist Metal Bronze Mosaic 300X320mm

$39.90 per sheet(incl GST) -

MosaicFX Caffine Long Black 300x300mm

$34.90 per sheet(incl GST) -

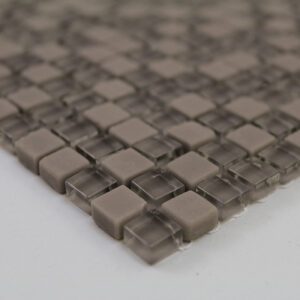

MosaicFX Caffine Mocha 300x300mm

$34.90 per sheet(incl GST) -

MosaicFX Chevron 3D Copper 288X300mm

$44.90 per sheet(incl GST)

Splashbacks FAQ's

The most common spacers used for tiles are 1.5mm, 2mm or 3mm and can be chosen depending on the desired look of your project. 1.5mm grout lines help minimise the look of grout and lets the tile or pattern stand out, a 2 or 3mm grout line is more traditional and shows off a tile laying pattern. For some tiles, like ones with a more handcut or wavy edge, we recommend a larger 2 or 3mm grout line as the tiles won’t line up as perfectly as a straight cut edge.

This is very dependent on what look you are going for, most people use a standard range of grey depending on the colour of the tile. Contrasting if you want to make the look stand out, or a similar colour if you would like to blend the grout in with the colour of the tile.

Tiles can range in price for a couple of different reasons, the main one being where they are sourced from. If for instance we import a tile from Italy the price of shipping is far more than say importing a tile from Australia.

Another factor is how much we import, we may import 500m2 of one tile and only 50m2 of another, giving us greater buying power.

We are constantly bringing in new ranges of tile and as older lines stop being produced we lower the price on these to free up more space in our warehouse.

The wide variety of types, finishes, sizes, shapes, colours and patterns of tiles offer a broad range of design possibilities.

The low water-absorption qualities, hardness and durability of many tiles provide a durable, low-maintenance surface finish for a range of internal and external applications. As with all building materials, tiles perform best when correctly selected and installed. They will then offer a surface finish that is:

- Hard and durable

- Fire and heat resistant.

- Chemical resistant.

- Hygienic.

- Stain resistant.

Many porcelain products are produced with rectified edges. Typically these tiles have very square edges as a result of cutting or grinding processes which produce tiles with very precise dimensions and permit installation using narrow grout joints.

If the area is fairly regular in terms of overall dimensions, 10 per cent extra should be enough. However, if the tile in question is an unusual shape, or the area to be tiled is a complex shape then 15 per cent is probably a better figure. Having a few spares is a good idea, because if you need more of the same shade (batch number) in the future it may not be available.

Tiles may vary from batch to batch, as shade variation is regarded as an inherent feature of tile production.

We will only supply one batch of tiles for a project unless prior agreement has been made, so if you need to re-order quote the shade or batch number which appears on the box.

A lot of contemporary tiles replicate the appearance of natural stone or timber, and they vary in appearance in an attempt to mimic the natural product.

A scale has been introduced to communicate the degree of variation intended.

V1: Uniform Appearance - Minimal differences among tiles from the same production run.

V2: Slight Variation - Clearly distinguishable differences in texture/pattern with similar colours.

V3: Moderate Variation - While colours present on a single tile is indicative of the colours expected on the other tiles, the amount of colours will vary significantly.

V4: Substantial Variation - Random colour differences between tiles so one tile may have totally different colours from that on other tiles.

Glazed products are already stain proof and generally do not require sealing meaning they consequently are a popular choice for residential situations (especially bathrooms) as they are easy to clean and maintain. You may apply a penetrating sealer on your unglazed tiles or your grout joints. The penetrating sealer is an invisible, stain resistant shield that is absorbed into the surface.

Some unglazed products have a surface treatment (Nano seal) applied during the final stages of manufacturing which penetrates the surface pores and assists in resisting staining. However some products – especially polished porcelains where small “micropores” have been created during the polishing process – may require sealing to protect against staining. Ask one of our team in store for more information regarding this.

Explore other categories

Can’t find what you are looking for, check out some of our other tile categories.